TECMAT aims to develop a novel type of thermal and electrical conductive compounds - with a high conductivity and an improved processability in a wide range of processing techniques - to broaden the application scope of conductive composites.

Newsletters

Tecmat Newsletter 02

Table of contents:

- Recap

- Influence viscosity

- Influence of dilution and competibilization

- Compounding vs. dry blending

- Prolongment of project

- Save the date! 14/10/2022

Tecmat Newsletter 01

Table of contents:

- Project presentation

- Filament extrusion

- Influence of the viscosity ratio

- Save the date! 22/09/2021

Downloads

The challenges for the industry

Thermal and electrical conductive thermoplastic materials are very interesting in a large range of applications, including textiles (monofilaments, knitted fabrics etc.) and compact plastic (injection molded) parts.

Conductive plastics provide lightweight, integrated multi-functional and complex design solutions vs. metal structures and have recycling advantages.

Although conductive thermoplastic compounds are already available on the market, their widespread breakthrough in lightweight, multifunctional applications is limited by certain obstacles. The most important issue is finding the balance between a high conductivity and a stable and easy processability.

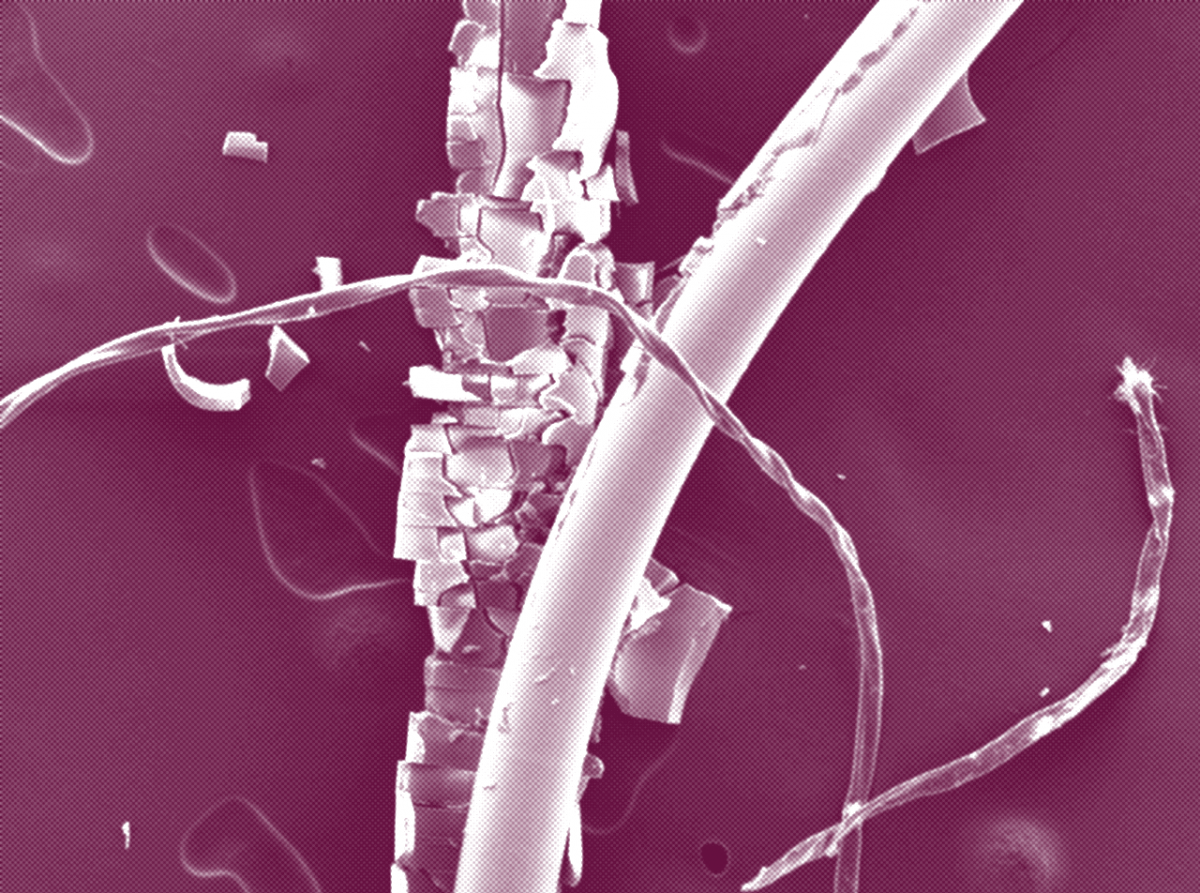

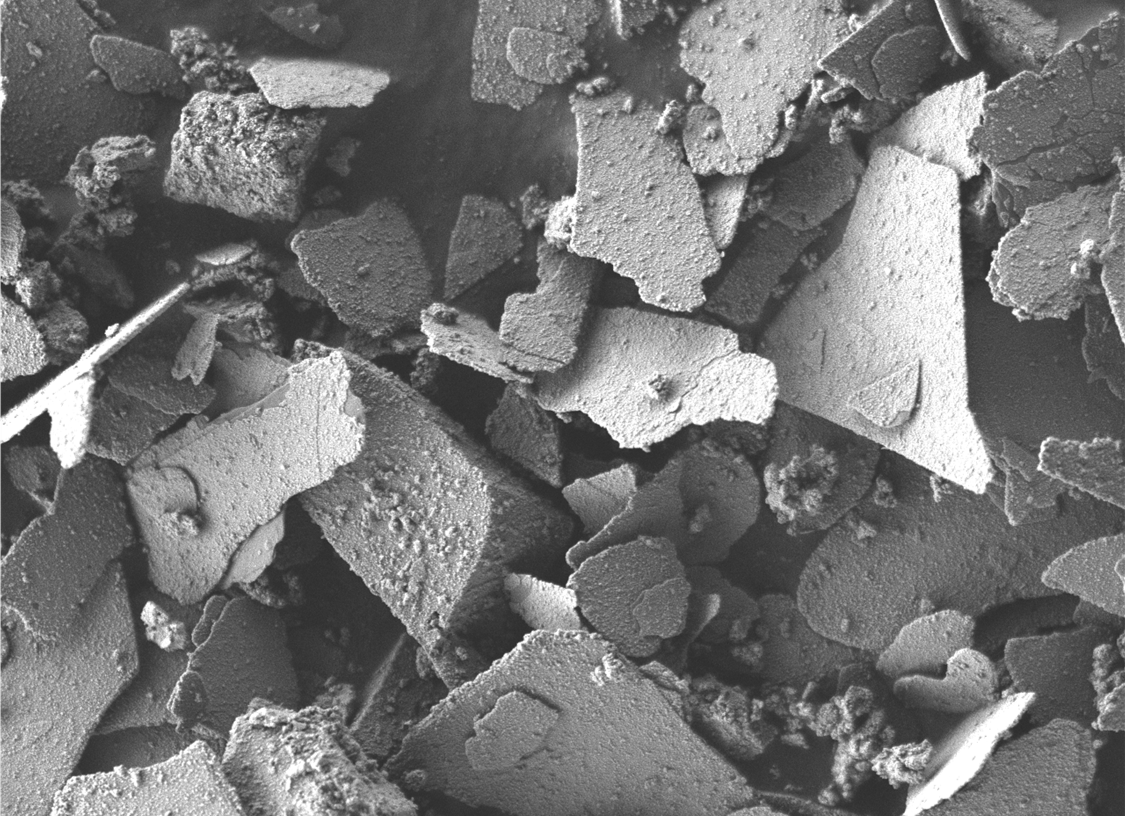

Conductive fillers significantly raise the viscosity that actually complicates the processing of thin-walled parts and textile fibres. Due to orientation and agglomeration of the fillers, the conductivity might drop during processing. Furthermore, the conductive fillers affect the resulting mechanical properties, for example by reducing the impact strength.

Therefore, the innovations proposed within TECMAT are essential.

The solutions of TECMAT

The basic idea is to create a composite, consisting of medium viscosity conductive composite domains in which the conductive fillers are concentrated and that is embedded in a low viscous matrix polymer. With this combination, the viscosity of the composite melt can be kept low compared to classical conductive composites with conductive fillers in a one-phase matrix at comparable levels of conductivity. The conductive domains are deformed during processing, forming a conductive network in the matrix polymer of the final part (“coalescence approach”).

Approach

This ambitious goal will be approached as follows:

- The use of immiscible polymers in order to achieve a conductive micro- and nanostructured network of the conductive polymer in the surrounding non-conductive matrix

- The use of special compounding for the production of the new multi-component composites

- As the micro- and nanostructure of the final material is formed during the processing of the melt for shaping the final part, the influence of the processing parameters and flow patterns on the structure formation and conductivity levels will be studied in order to produce the intended conductivity levels and the spatial distribution of conductive areas in the part

- The use of compatibilizers for the improvement of the processability of the multi-component melt and the thermal, electrical and mechanical properties of the final parts will be studied

Triggered by the project results, the (SME) members will be stimulated to develop their own thermal and electrical conductive products with improved properties. Protective clothing, smart or heated textiles, heat dissipators, housings for mobile devices, decided aspects of electromagnetic shielding and copper cable replacement are some of the many possible applications.

TECMAT will thus generate opportunities along the entire textile and plastics production value chain: producers of polymers and additives, formulators, compounders, textile companies, plastic converters and textile and plastic equipment providers.

Project financing

Cornet project, co-financed by Vlaio

Project no. HBC.2019.2687

1/6/2020 – 30/11/2023