Advanced recycling of multilayer plastics and textiles

By using an integrated approach for debonding on demand technology

It is expected that producers of packaging materials and textiles will suffer large losses when they fail to market products that are in-line with the Green Deal of the European Commission. Innovations in the sustainable use of materials with improved recyclability will offer huge business opportunities.

As requirements for a responsible and sustainable use of resources become increasingly stringent, recycling and reuse are highly important concepts to the packaging and the textile industries. An efficient recycling processes requires that complex materials be separated, a real challenge for both sectors since their products typically have a multi-layered composition.

Today, there are no viable commercial solutions to face the challenge of separating (debonding on demand) multi-layered EOL materials.

What is Debonding on Demand (DoD)?

DoD means the intentional separation (or reduction of adhesion) of an adhesive joint or separation of a coating from a substrate.

The debonding process is initiated by a so-called trigger, e.g. a heat or a light pulse. Ideally the trigger mechanism is not initiated in the period when the product is in use.

Today only a very limited set of commercial solutions exist for DoD. Most approaches in science and in industry focus on the modification of the adhesive, by the incorporation of smart particles or by a chemical modification of the adhesive polymer network.

For example: by applying a heat trigger pulse, the embedded particles expand or the polymer backbone dissociates after being triggered by a UV light pulse.

Both mechanisms provoke a weakening of the adhesive resulting in a full and clean separation.

The problem

However, many issues still need to be solved. By modifying the adhesive its properties become too strong preventing their use. Moreover, the modification of the adhesive is not always suited to the needs of the textile and packaging industries:

- The adhesive film (due to the embedded particles) is too thick for industrial laminating processes for packaging

- The required trigger cannot be applied or the crumpled state of the packaging slows down the debonding and by consequence the recycling process

- After debonding, the separation of the materials is not compatible with the process flow in the recycling station

The solution

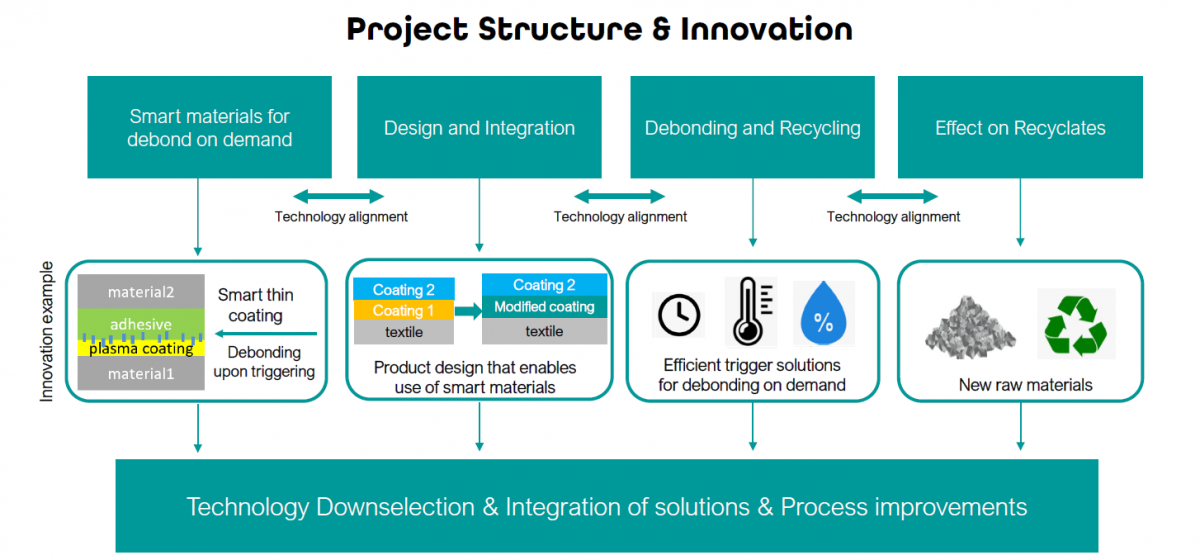

An integrated approach for DoD

Therefore, the problem cannot be solved by just developing a smart adhesive alone, without looking at the whole picture.

Simultaneous innovation and a gradual shift and merge of conditions and requirements in all steps is required to find a commercial solution to improve recycling in the textile and packaging market, which will enable the circular economy for plastics and textiles.

DEBOND proposes to develop new materials and processes to improve the debonding performance of flexible packaging and textiles applications. The project will combine the skills of the partners along the full product line and the ones of the targeted SMEs and multinationals. The developments will focus on two market sectors facing similar challenges: flexible packaging and textiles.

Project managers

Stijn Corneillie

Researcher "Plastic characterisation, processing & Recycling"

sco@vkc.be

+32 56 29 27 12

David De Smet

Researcher "Textile Functionalisation & Surface Modification"

dds@centexbel.be

+32 489 871 019

+32 9 241 86 84

Downloads

Project financing

Cornet project, financed by VLAIO (Flanders) and AIF (Germany)

start: 1 March 2023

end: 28 February 2025