The evolution of the COVID-19 pandemic demonstrates the need for continued innovation to efficiently mitigate the spread of the virus.

Centexbel, HoGENT and VITO are translating the lessons learned into actions to help the industry solve the identified pain points from the first wave in the best possible way.

Challenges for the textile and clothing industry

During the first COVID-19 peak, (textile) companies turned their production upside down to mitigate the shortage of masks for healthcare and society. It became clear that the required machinery (for the production of nonwovens and the assembly of face masks) is not available in Flanders and that the product knowledge was insufficient.

Companies used their production apparatus and available materials to provide protective equipment. However, not all products met the safety and comfort requirements.

Moreover, a large number of companies had to drastically reduce or even stop their activities, partly because of sick employees, partly because they could not work safely. Even if social-distancing precautions could be taken, employees were concerned about being infected by colleagues, customers, professional relations. The lack of protective equipment contributed to this.

In view of the exit after the first wave, massive efforts were made by (textile) companies and private individuals to produce community masks, which logically focused on safety.

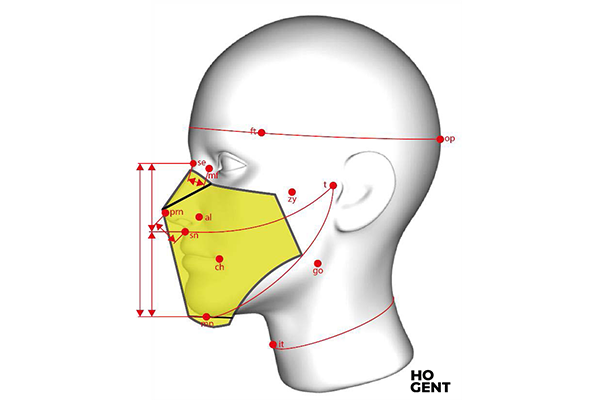

However, for the people in the field, wearing a face mask was not always comfortable due to insufficient breathability, lack of heat and moisture dispersion (fogging glasses), a poor fit, because the mask is either too big or too small (adult vs. child as well as anthropometric differences).

Poor fit compromises safety because the wearer tends to frequently touch mask and face, creating a significant contamination risk.

Solutions of COVVID-PBM

The 3 project partners - Centexbel-VKC, HoGent and VITO - each contribute their expertise in:

- materials and processes

- comfort & fit

- legislation

- test protocols and standards

Aims

The aim of this project is to disseminate information about which materials and processes can be used to make safe, comfortable and well-fitting face masks. This will result in better fitting face masks that give a safer feeling. In combination with a pleasant wearing comfort, employees will be able to work with face masks throughout their shift and citizens will be able to enter busy environments with peace of mind.

The applicable legislation and the required quality and guidelines for maintenance will be clearly displayed.

This project will ensure that Flanders can provide its own protective equipment (respiratory, medical, community and artisanal masks) so that citizens and workers can move around safely and comfortably in society and at work.

This will have an economic impact on the various target groups: textile and clothing companies, employees and staff in shops and catering establishments.

Reports & Results

After filling in your coordinates and selecting the document(s) you would like to consult, you will be directed to a webpage where you can download the desired file(s).

Please consult our privacy policy rules

Project managers

Researcher Textile Functionalisation & Surface Modification

R&D manager Textile Functionalisation & Surface Modification

Project financing

Collective Research & Development and Collective Knowledge Transfer (COOCK), financed byVlaio

Project HBC.2020.2741

1 October 2020 – 30 September 2021