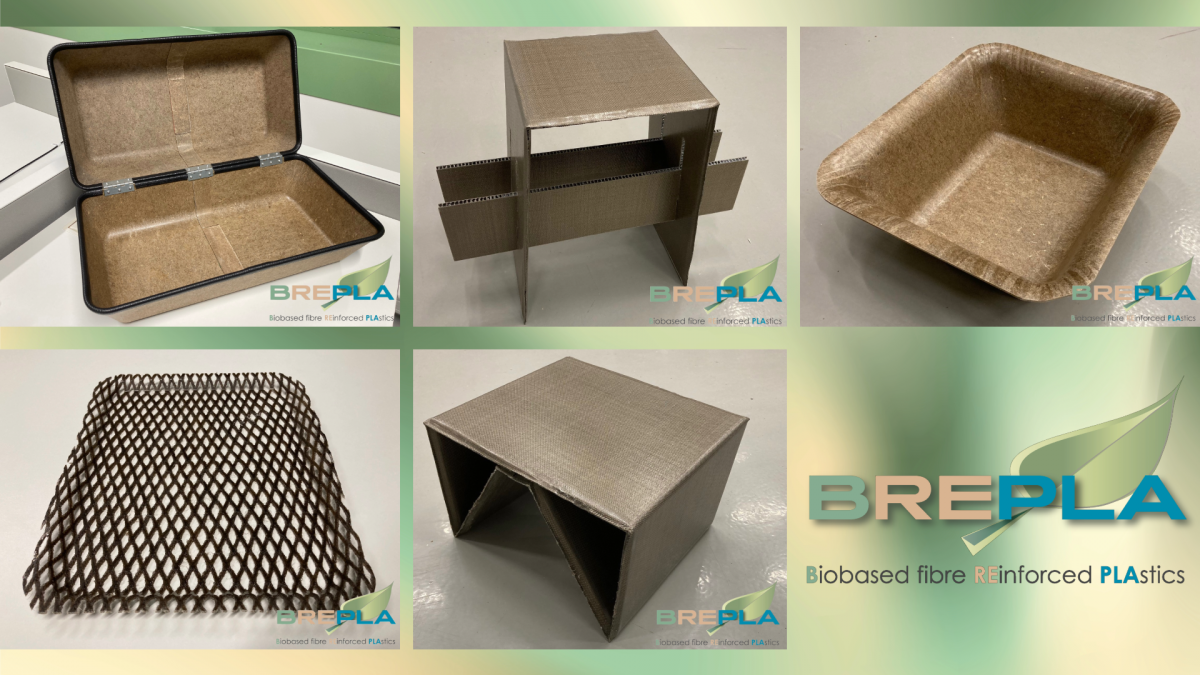

To show the potential of bio-composites, we made several BREPLA bio-based demonstrators.

The chosen demonstrators focus on different materials and processing methods, and on sectors that are considered most mature for integrating bio-composites on a larger scale.

1. Piece of furniture

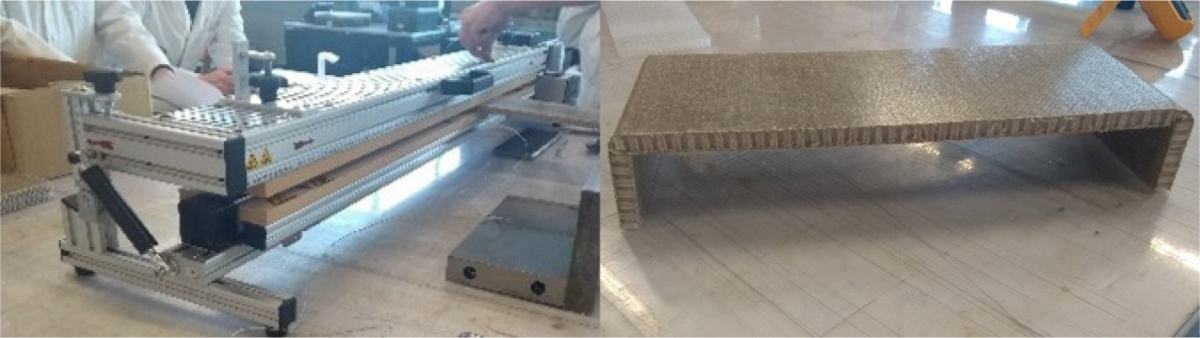

It was decided to start from a sandwich panel consisting of a PLA core and a flax/PLA or basalt/PLA skin.

We first tested whether the sandwich panel could be easily converted into a 3D structure via folding. This involves heating locally with a heatable bending machine (see picture) to above the melting temperature of PLA, after which the panel is folded into the desired shape. Folding is a fairly simple process and avoids the use of expensive molds and presses so that the manufacturing process is relatively cheap.

In a second phase, Sirris and Centexbel worked out the design of the piece of furniture together with 5 companies involved. Taking into account the maximum dimensions of the sandwich panels and the pliability of the whole, a stool design and coffee table design were proposed.

In the next phase of the project, Sirris will make prototypes of these 100% bio-based furniture together with the partners involved after a few production test runs.

2. Roof top box

Here we started from a 50% hemp/50% PP nonwoven that is first consolidated into a flat sheet and then thermo-compressed into the desired structure.

The pre-consolidation ensures a homogeneous distribution of the matrix over the fibers so that the fibers are completely impregnated with the polymer. Good pre-consolidation ensures optimal utilization of the fiber properties and enables a short product cycle during 3D forming.

Immediate pressing of the nonwoven mat into a 3D mold may lead to local areas where the consolidation is not sufficient and thus may lead to weaker mechanical properties.

The figure below shows from left to right how the box was produced. This process will be used to produce the final roof top box, where the thermo-compression will take place in an adapted mold.

3. Ping-pong bats

Biocomposite ping-pong bats

flax, bio-epoxy

4. design tray

The idea behind the third demonstrator is that an aesthetic product can be developed without the need for expensive mold and manufacturing process.

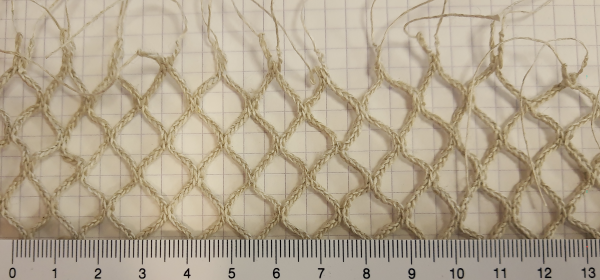

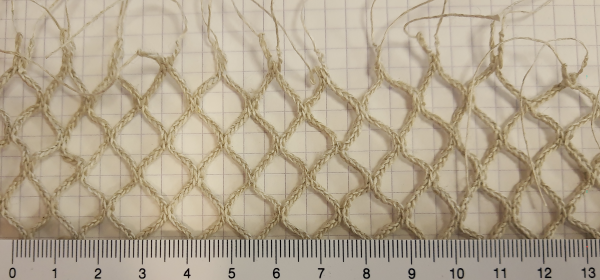

We start from an open flax fiber structure that is impregnated with a bio-epoxy via a hand lay-up process.

By draping it over a mold we create a design tray.

Project financing

Collective Research & Development and Collective Knowledge Dissemination (COOCK), supported by Vlaio

Project HBC.2020.2567

1 January 2021 – 31 December 2023