As consumers are more and more concerned about the origins and sustainability of products and as European regulations are becoming increasingly stringent in this respect, the need to find alternatives to fossil-based raw materials is urgent.

Challenges for the coating industry

The coating industry too has to adapt to the new requirements. Coating developers have already reduced the emission of volatile organic compounds (VOCs) by partially switching from solvent-based to water-based coatings, and manufacturers are asking for alternative, environmentally friendly coatings to be included in their product range.

Although everyone in the value chain is convinced of the usefulness of bio-based coatings, their introduction is stagnating.

European research and surveys of Flemish companies show that there are several reasons for this delayed breakthrough, one of these reasons being the misunderstanding that bio-based coatings would be less efficient than traditional coatings.

However, there are immense opportunities to develop bio-based coatings thanks to the increasing supply of new bio-based building blocks from (non-food) biomass. Some bio-based coatings have even better or wider application possibilities than fossil-based coatings.

The way the coating is applied often appears to have a greater impact on the proper functioning of the coating layer than its composition. For example, (job) coaters do not have sufficient know-how to process and apply bio-based coatings correctly.

Although Flemish coating developers want to incorporate the new bio-based raw materials in their coatings, the start-up is complex, time-consuming and expensive.

Moreover, it is impossible to replace certain chemicals on a "one-to-one" basis. Because many coating developers are not familiar with the composition of bio-coatings, they have insufficient insight into the possibilities and bottlenecks during their development.

Internationally, research focuses on the development of building blocks and not on the validation of bio-coating formulations and their application.

Solutions of Biocoat

The BioCoat project aims to accelerate the transition to bio-based coatings based on industrially available bio-building blocks by providing coating companies with knowledge about the formulation, application, performance and applications of bio-based coatings.

Tools

- A white paper provides an overview of the applicability of market-ready organic building blocks and the development process to integrate them into their own product range: a bio-based coating, the application or the integration in an end product.

- The project will follow the development path of four "target formulations" (polyurethane (PU), polylactic acid (PLA), acrylic and epoxy) to demonstrate the transition to a high-quality bio-based alternative in practice. This knowledge base and insights can serve as a starting point for companies to accelerate the application of bio-based coatings for their own markets.

- A coating application will show how coating companies using traditional techniques (squeegee coating, impregnation, spray coating, dip coating or flow coating) can correctly process and apply bio-based coatings to textiles, plastics, composites and metals. Guidelines provide them with insight into the impact on their production process and the required developments and investments.

- Hands-on workshops, demonstrators, white paper, various publications and presentations are geared to the absorption capacity, knowledge level and role of companies in the value chain. The knowledge transfer will encourage companies to accelerate their innovation trajectory.

Evaluating new applications for bio-based epoxy coatings with enhanced performance and lifetime

02 June 2023

Pieter Samyn & Patrick Cosemans (Sirris)

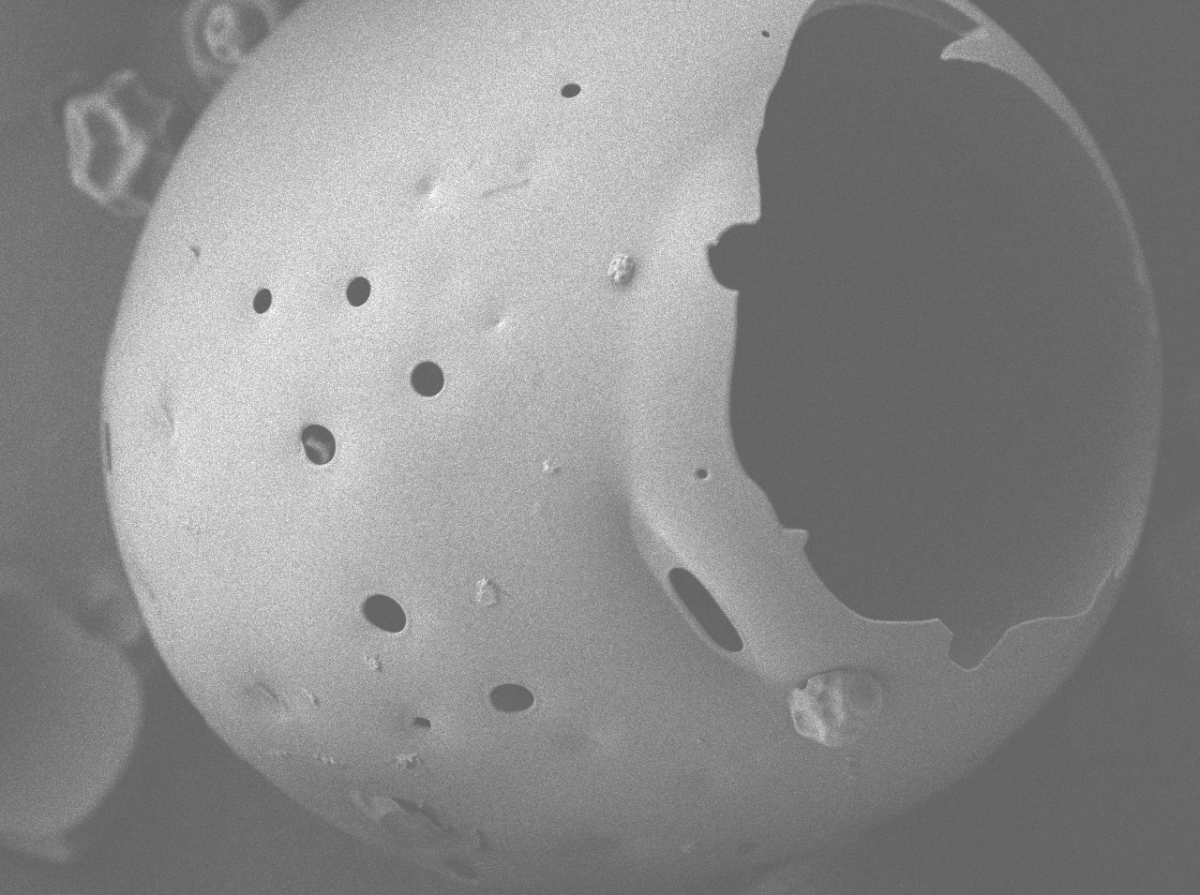

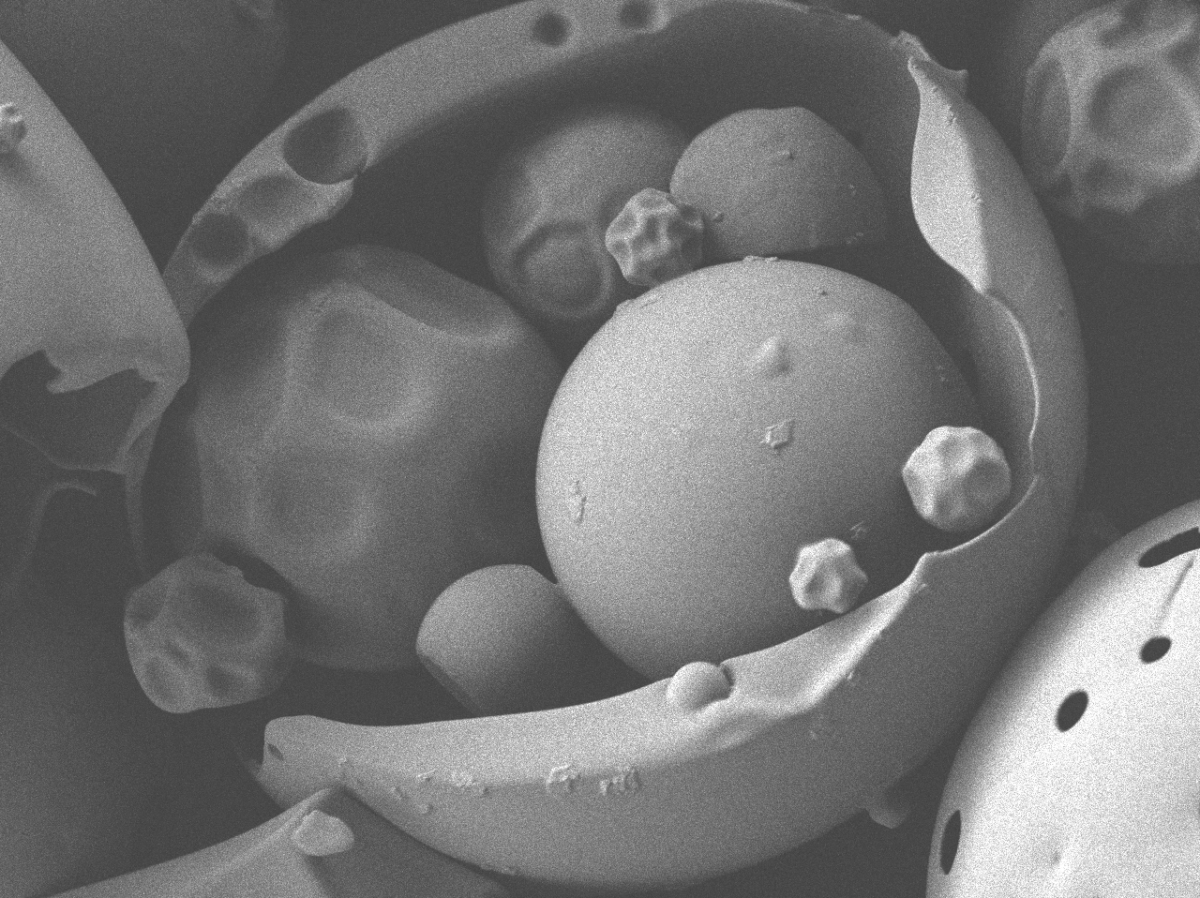

Epoxy resins are still a first-choice polymer for applications in adhesives, composites and protective coatings on wood, concrete or stone because of the good balance in mechanical properties and long-term protection. Their use, however, is somewhat limited due to some drawbacks in intrinsic properties and because of environmental reasons, there is in parallel an increasing demand for bio-based alternatives. To enhance the introduction of bio-based epoxy coatings, R&D in this field has strongly expanded in recent years. In this context, Sirris has made a screening study of different types commercially available bio-epoxy coatings. This study was recently published.

Project manager

Brecht Demedts

Researcher "Textile Functionalisation & Surface Modification"

Project financing

Collective Reseach & Development and Collective Knowledge Transfer (COOCK), financed by Vlaio

Project HBC.2019.2493

Collaboration Sirris & Centexbel

1 January 2020 – 31 December 2022